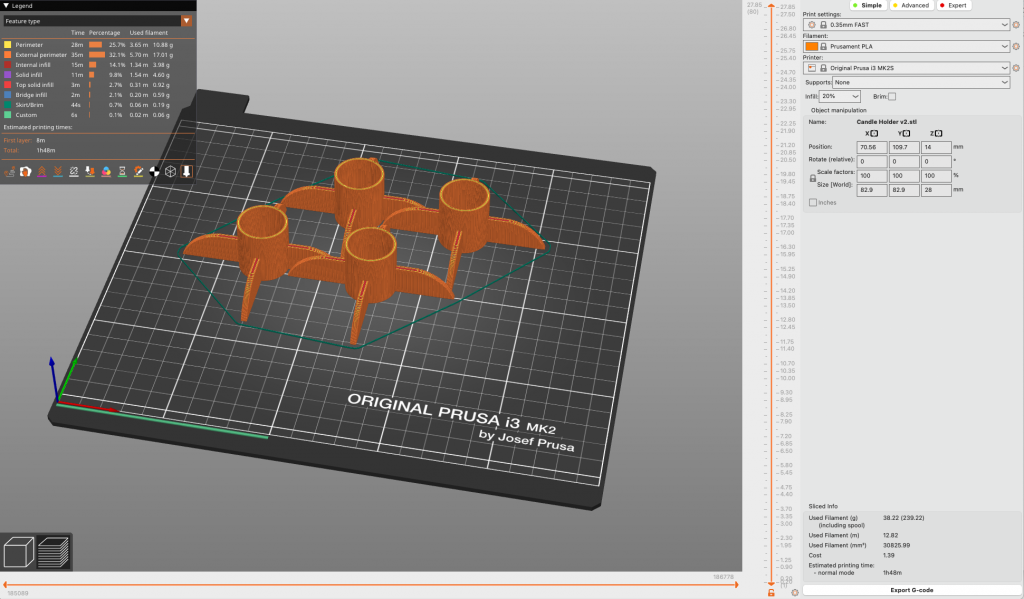

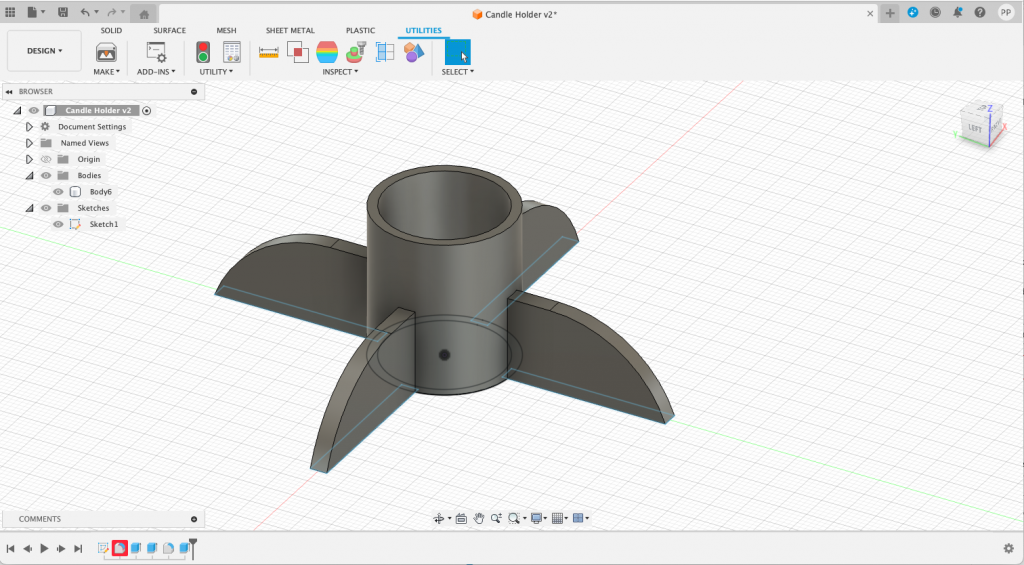

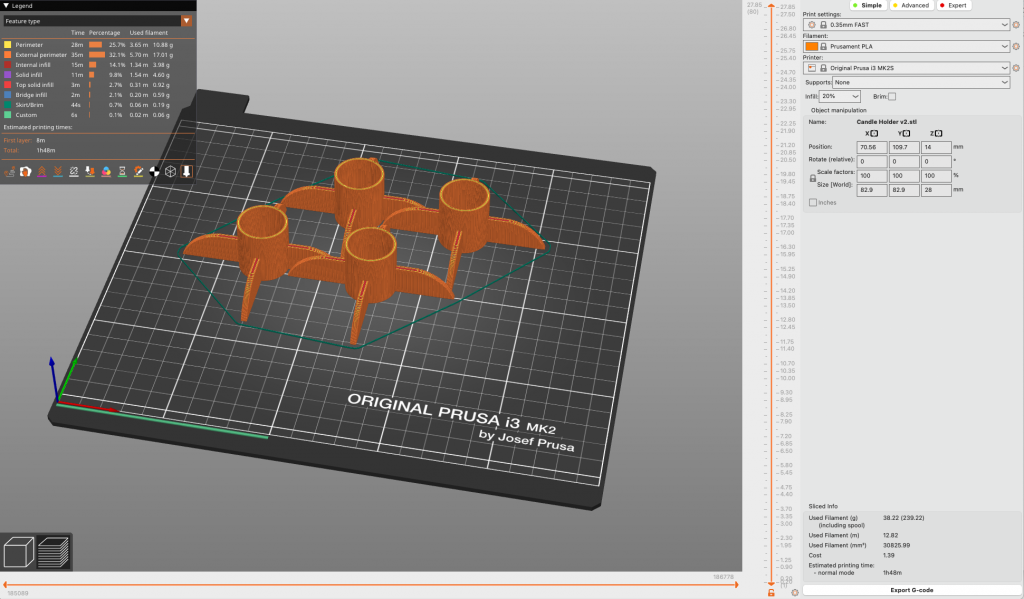

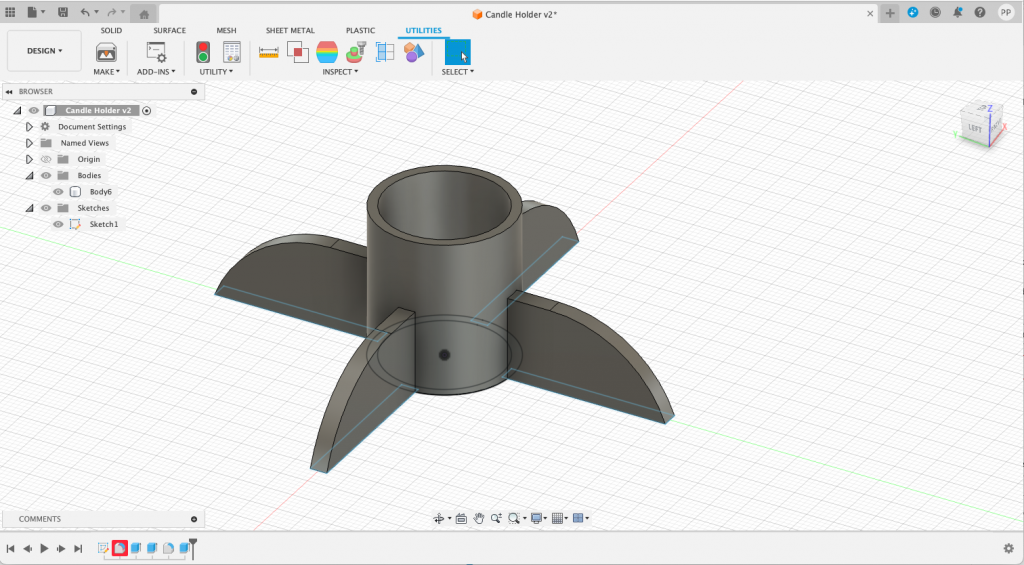

Printed a few candle holders for Christmas decoration.

Personal collective of ideas, thoughts and notes

Printed a few candle holders for Christmas decoration.

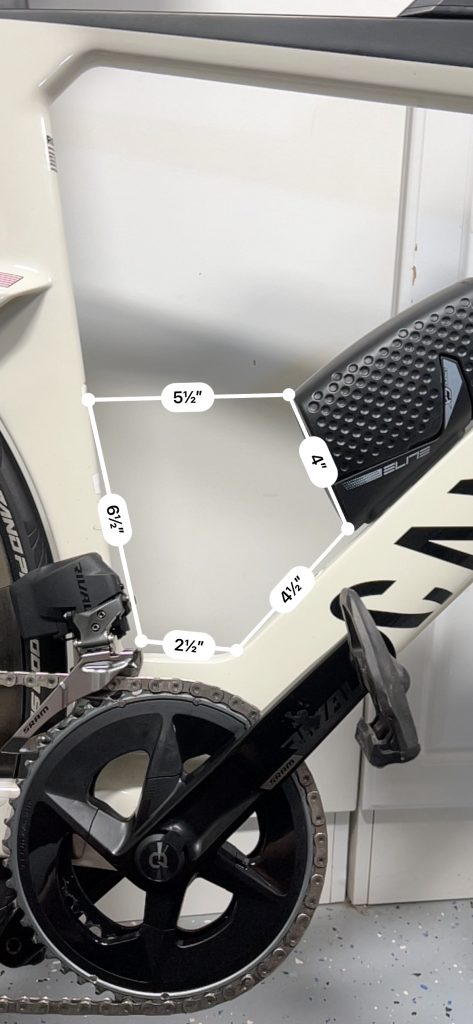

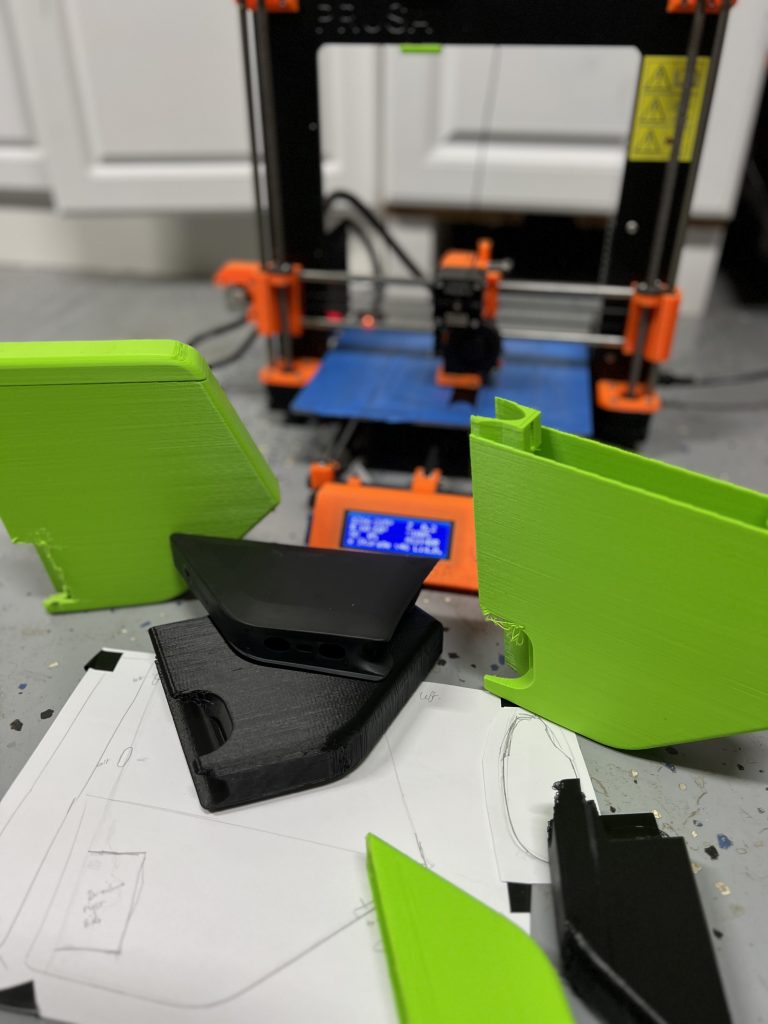

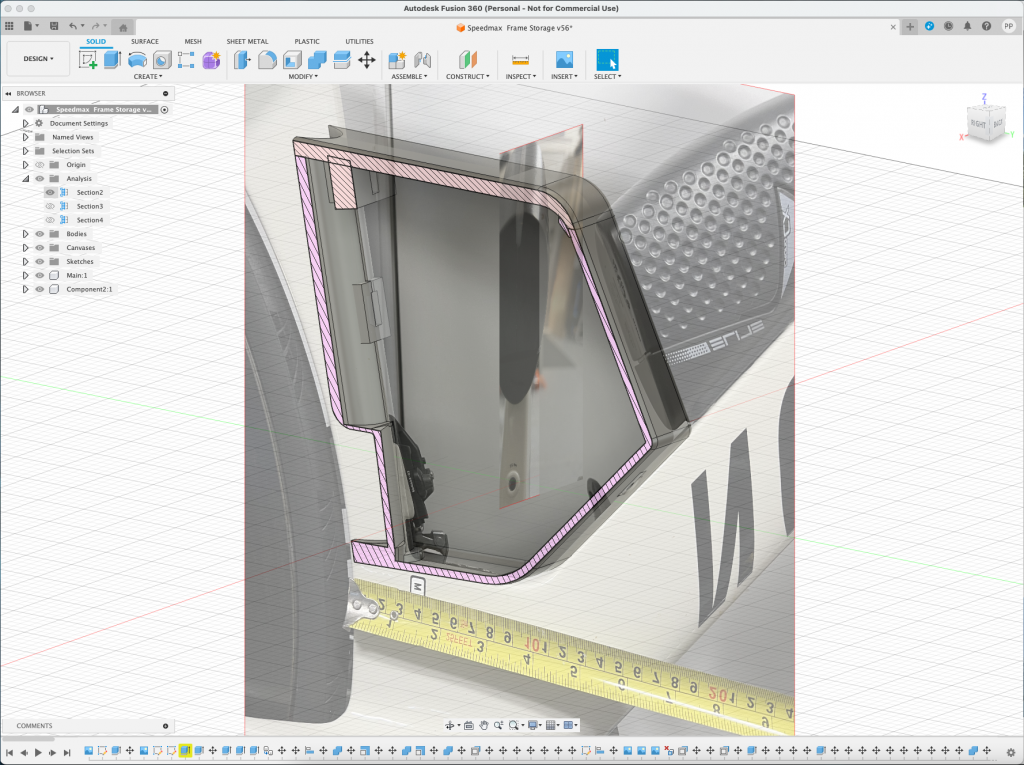

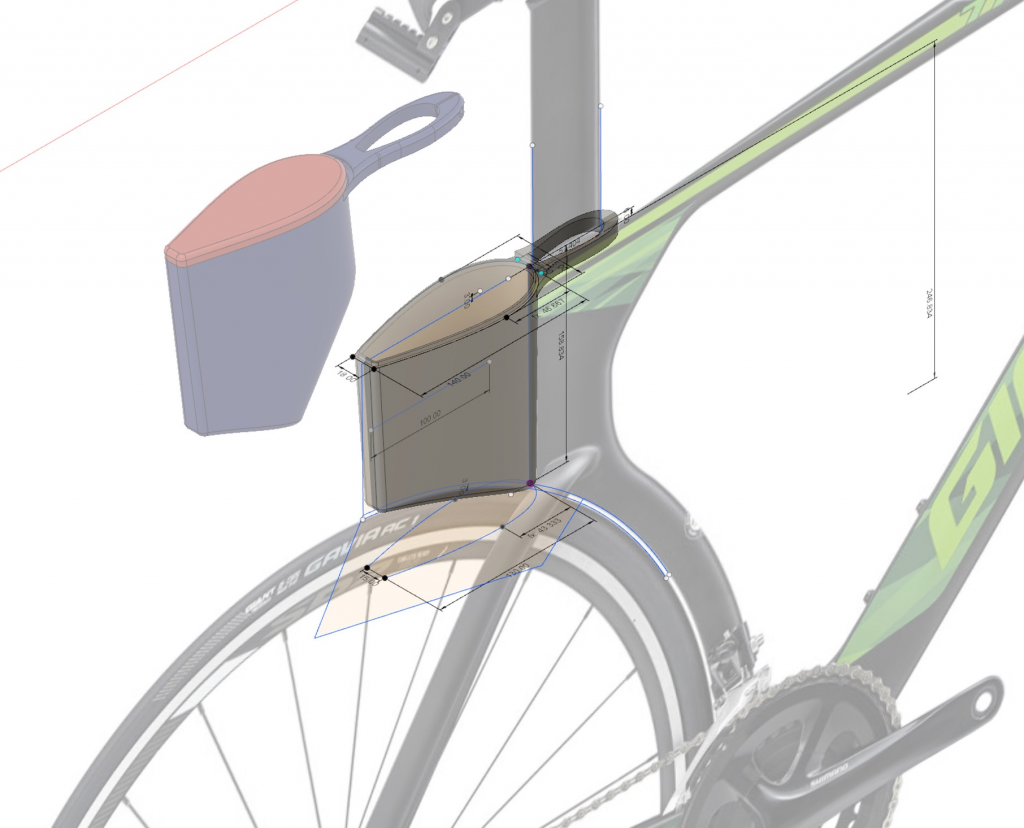

My 3D design skills and understanding of modeling around a physical object have come a long way since my first bike storage box, this one fits my 2022 Canyon Speedmax CF (Medium). The reason for designing and printing these is that while the bike has built in storage, it’s seldomly enough to be self sufficient during long rides. For full distance Ironman events, I take the following: (After mishaps, trial and error) 2 x Tubolito spare tubes, 2 x CO2 Cartridges, 1 x Dart puncture tool, 1 x Mini Pump, a Multi Tool and a Chain link.

Design: Autodesk Fusion 360

Printer: Prusa Mk2

Material: PLA

Print Time: 12 Hours

I have always enjoyed the concept of being immersed into a virtual world. One of my first experiences with VR was in roughly 1993 when our local arcade introduced a game from one of the OG gaming founders John Waldron called Dactyl Nightmare on a 1000CS. After that experience, I have always wanted to build a motion sim which gets you as close to reality as possible.

Last year I took the first steps and decided to put the initial blocks in place and start with sim platform that I could eventually add motion to. I purchased a Fanatic wheel base and thought it would be a great learning experience to build the steering wheel from scratch. Many of the components can be built versus bought which is what is keeping me motivated to eventually get the entire system together.

Designing, building and then using something you have made, has been one of the most rewarding and personally satisfying activities I have found in my life so far. I was born a tinkerer, always disassembling, trying to understand and improve or recreate.

My favorite TV show is “How it’s made”.

I have way too many expensive tools, printers, cutters and machines, and not a single one has made a significant return on the investment … but, what I have learned using them has been 10x …

Its not just the tool, its the tools to use the tool, the software to design the product, the process to start, run or finish the machine or product, the prep work, consideration and the functionality.

This weekends challenge, a better hook for a bicycle:

Want to laser cut one of your own or remix it? Check it out on Thingiverse

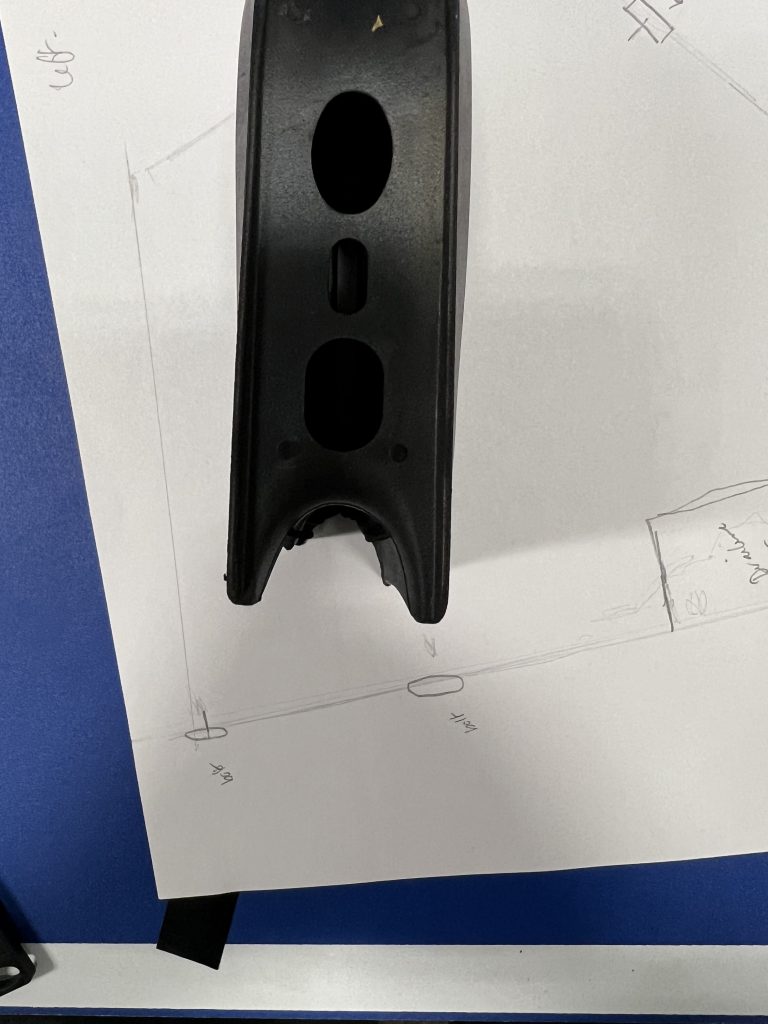

This is a vertical based bike hook for bicycles with aero (deep) front rims. Currently there are not many wheel hooks that keep the front wheel vertical and that don’t scratch the rim when putting the bike up.

The hook is lasercut using a glowforge and medium draft board (the material thickness is important as all the slots need to interlock). Assembly is slotting the parts together and installation requires two screws/anchors into the wall.

It was specifically designed for a Reynolds AR80, however, I believe other wheels with similar dimensions, depths or profiles should fit.

Problem: In cycling (and other applications) water bottles are a variety of shapes and sizes. This often makes them difficult to get in or be contained in a traditional bicycle water cage. This attempts to resolve this by offering an “expanding” cage.

Fun but ultimately bad patent idea to create an expanding water bottle holder.

I made a couple models/3D prints to proof it out, but decided against it.

Spring-Loaded Retention Bottle Cage for Bicycles

This invention relates to cycling accessories, specifically to devices for securely retaining water bottles on bicycles. It aims to provide enhanced bottle stability via a vertically applied spring-loaded retention mechanism.

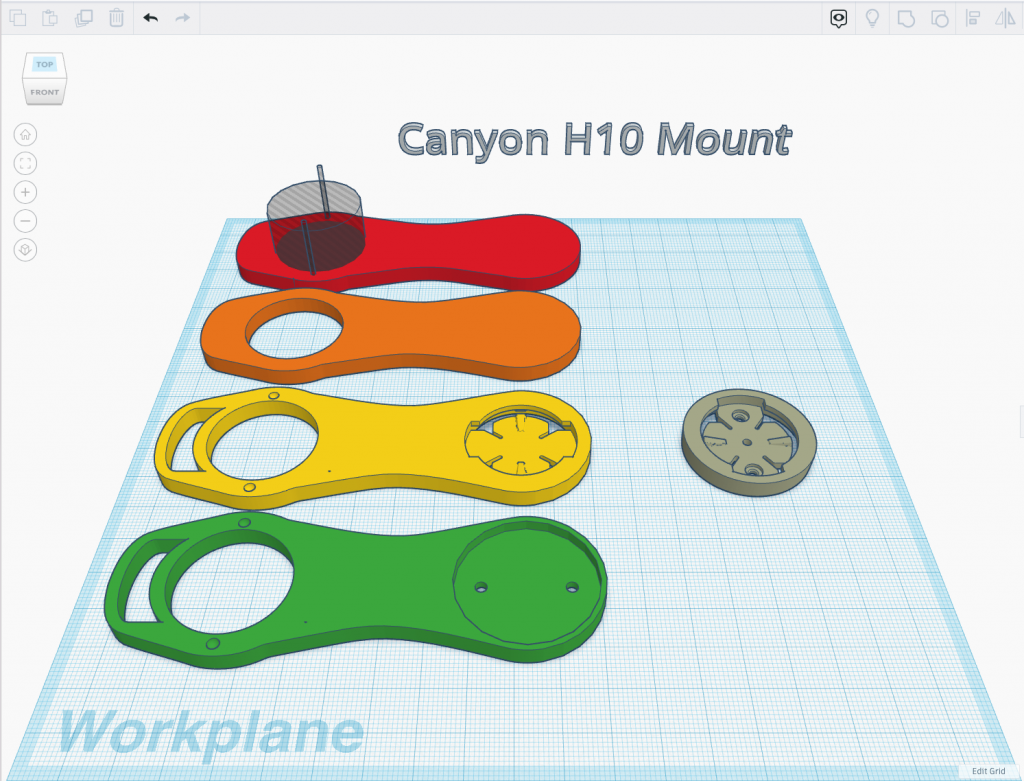

This was a fun 3D Printing project I threw together when I needed a mount for my Garmin 530 on my Canyon MTB. The Canyon mounts were out of stock and backordered for months, so I designed and printed a clone.

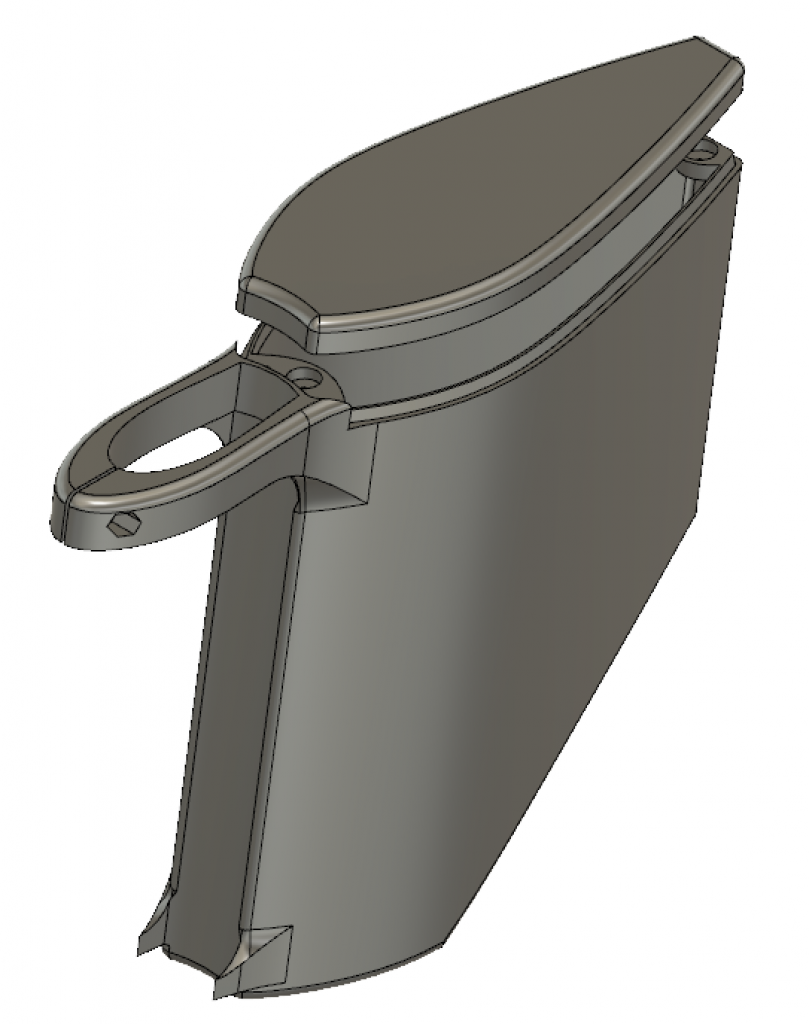

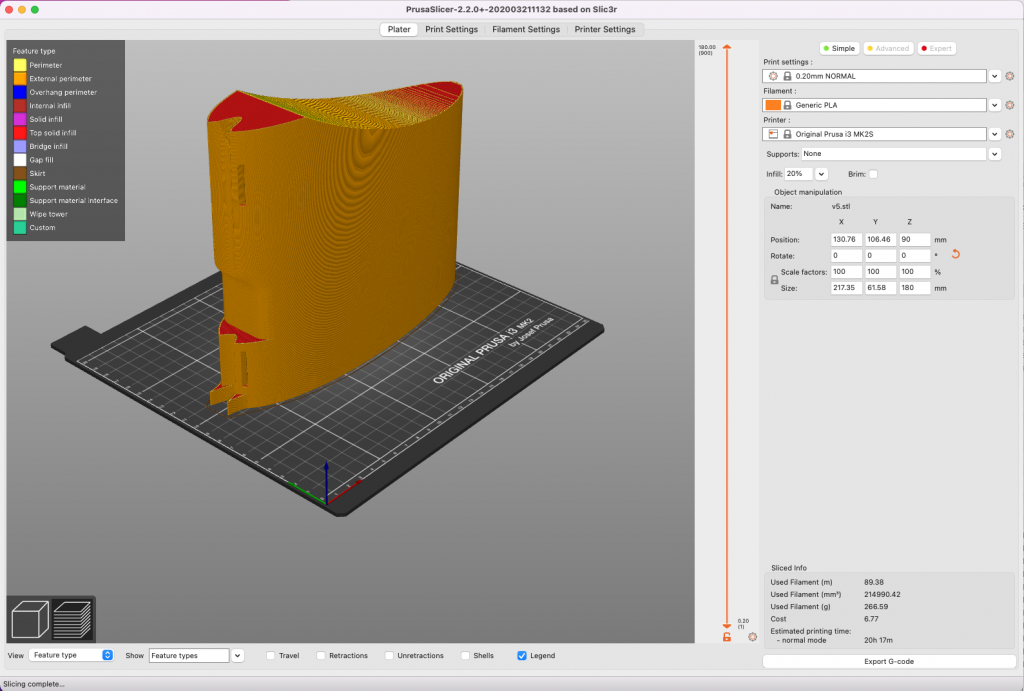

This was a challenging 3D printing project which I designed and built for my 2013 Giant Trinity. This was a 20 hour print using Fusion 360 for CAD. The challenging part was get the seat and seat tube profile to perfectly match the bike.

Inspiration

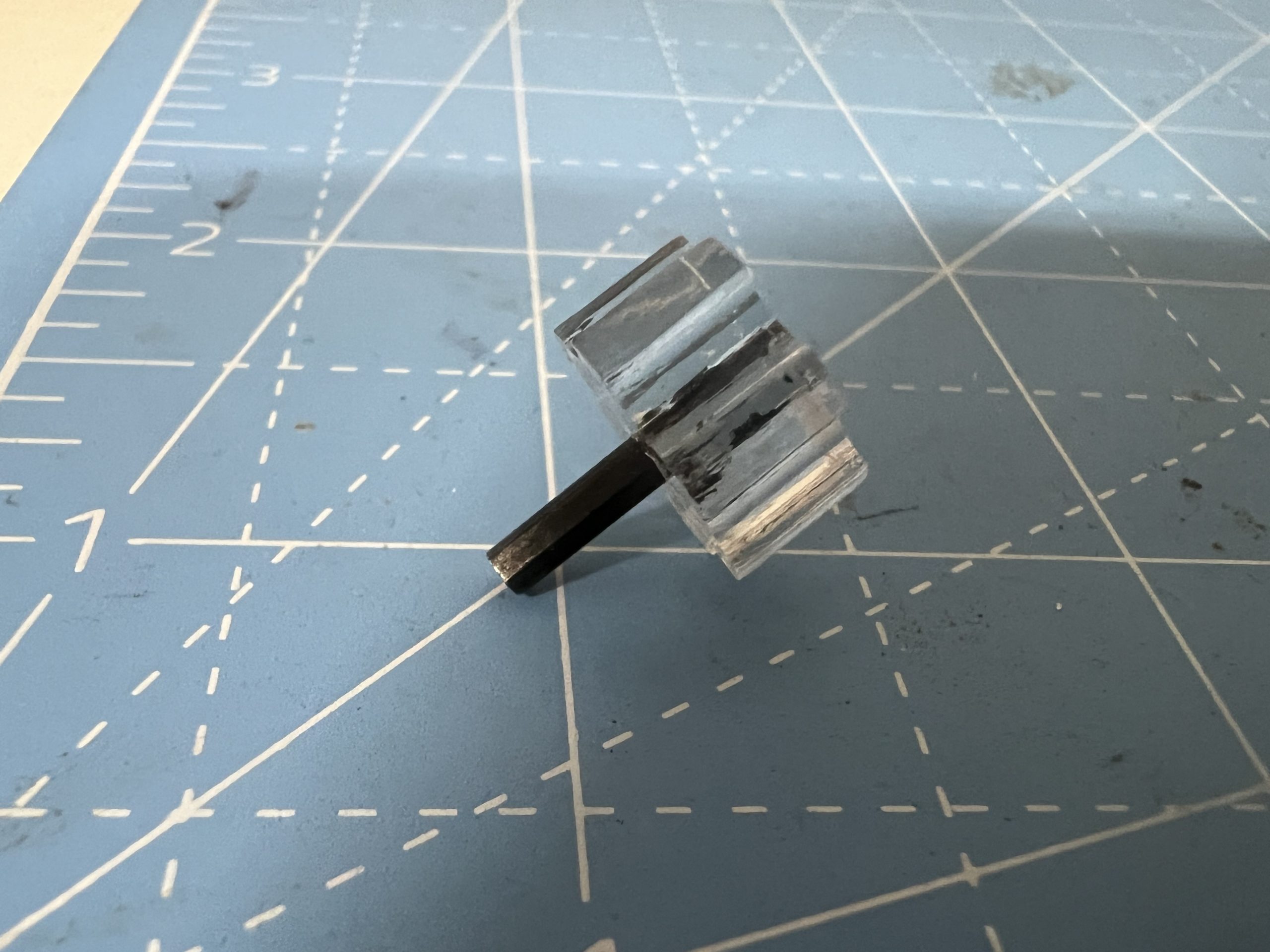

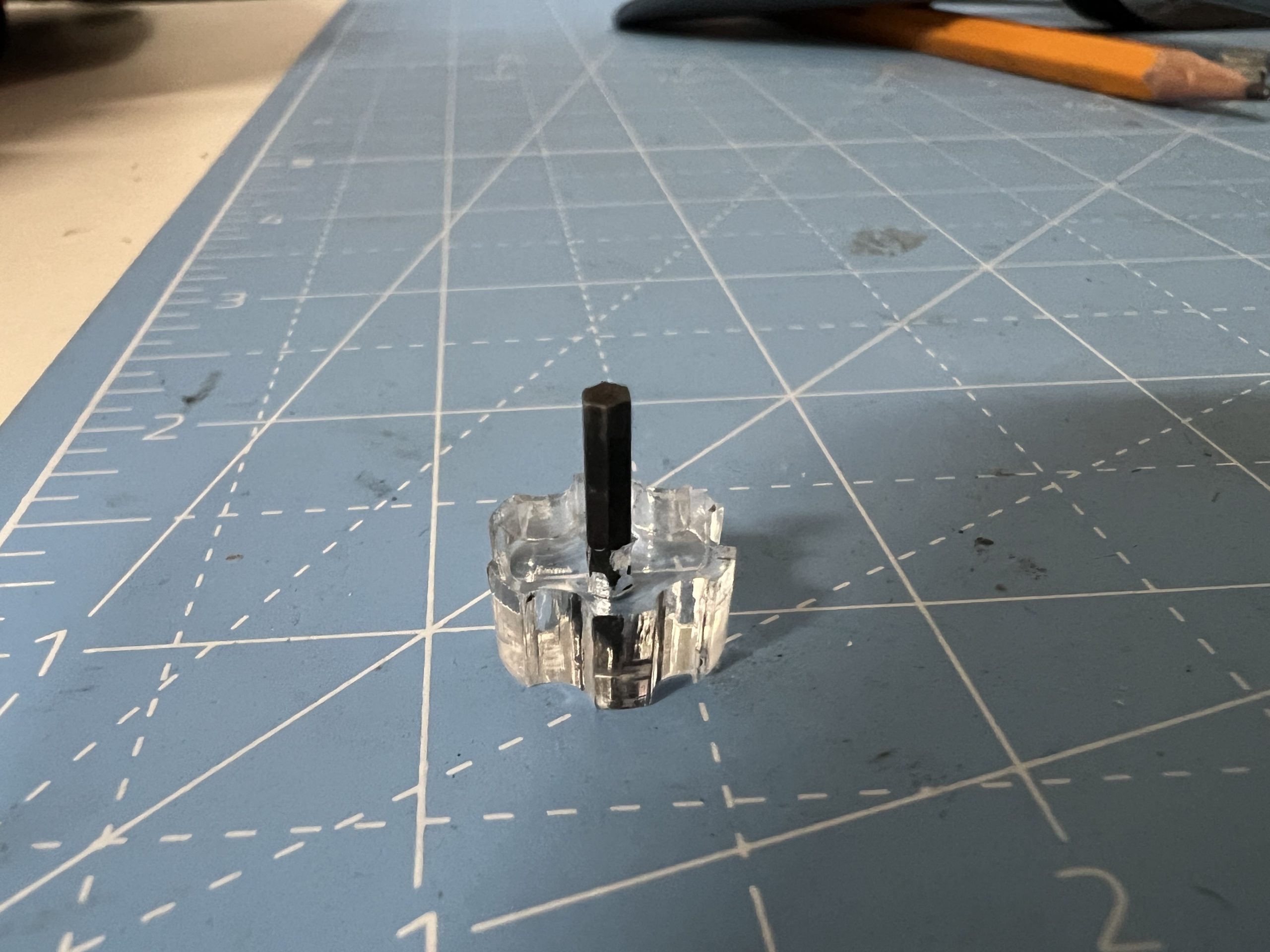

One of the smaller projects I have designed and cut, and probably one of the more useful. This small too lets you easily adjust the SRAM brakes reach point easily, since it is really difficult to get a tool or Allen wrench into the confined space.

This was cut out of acrylic and then a small section of Allen wrench heated and molded into the thumb screw.

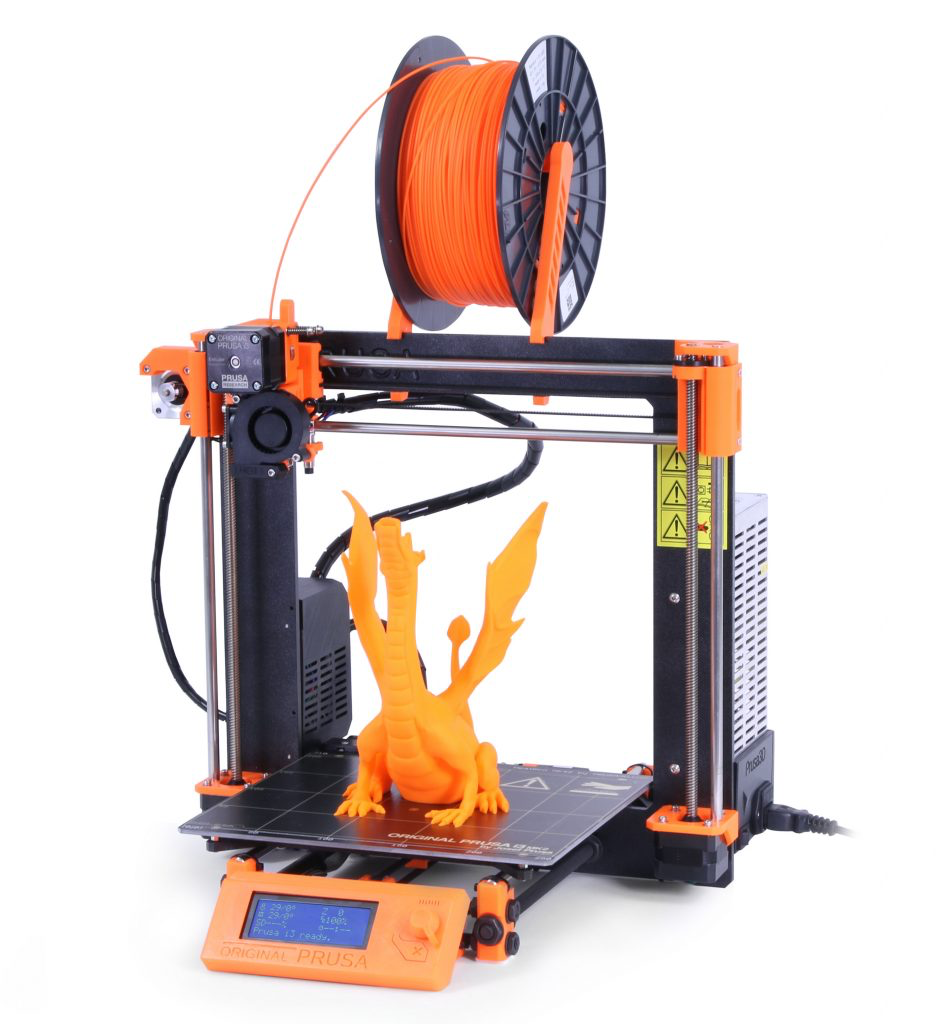

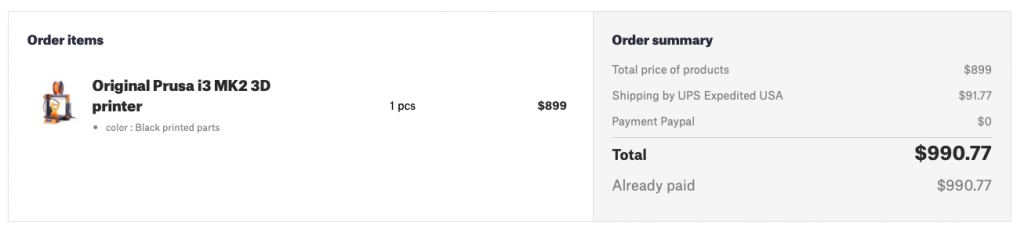

I purchased my first (and still only) 3D printer in 2016, after a considerable amount of deliberation and comparisons, I decided on a Prusa due to the build quality, company history and the great value the company offered.

This was the press release which pushed me over the edge to get one: https://blog.prusa3d.com/original-prusa-i3-mk2-release_4332/

I have printed around 100 different objects, ranging from practical to pathetic, it’s been a great tool for learning 3D CAD design with tools like Tinkercad and Fusion 360, and the art of invention and innovation. While with this machine the learning curve was fairly steep, I think its a great tool for teaching kids about design, engineering and manufacturing.

You must be logged in to post a comment.