After years of dreaming and ideating around making carbon fiber products of some sort, I finally had a need to build some custom parts for my triathlon bike. After spending a considerable amount of time reading, watching and listening to tutorials online, I took the plunge and purchased some starter materials. My initial plan was to work with 3D printed moulds and do wet layup.

I purchased a 3D printed started kit from Easy Composites. The shipping was a little expensive (they are based in the UK) but seemed to have the best products, prices and matching material requirements for my needs.

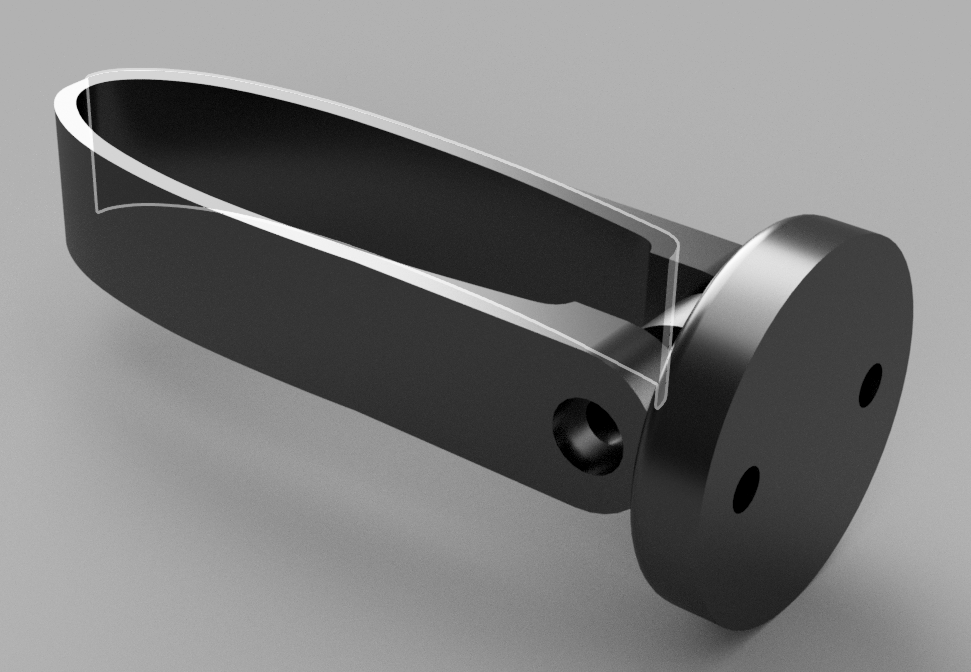

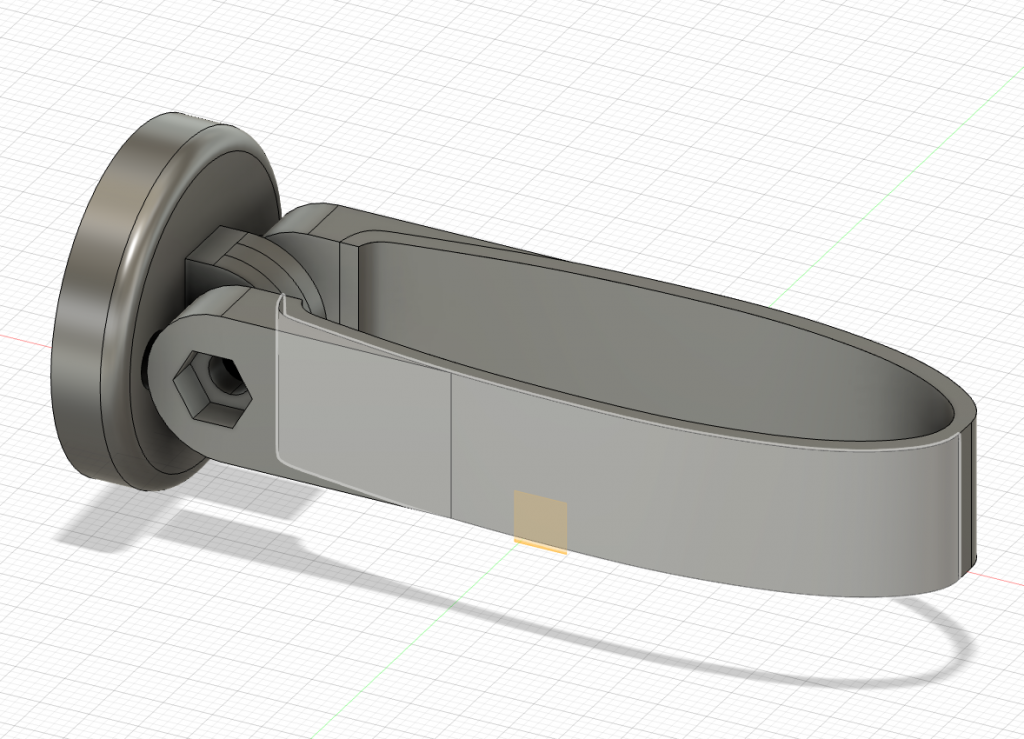

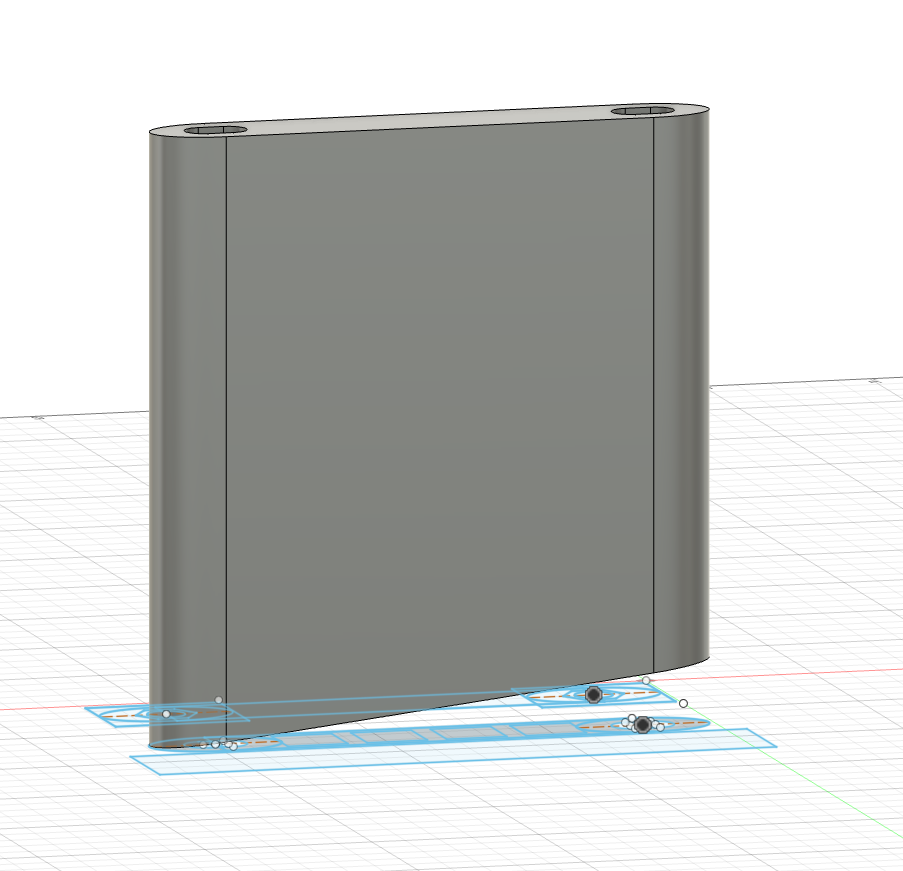

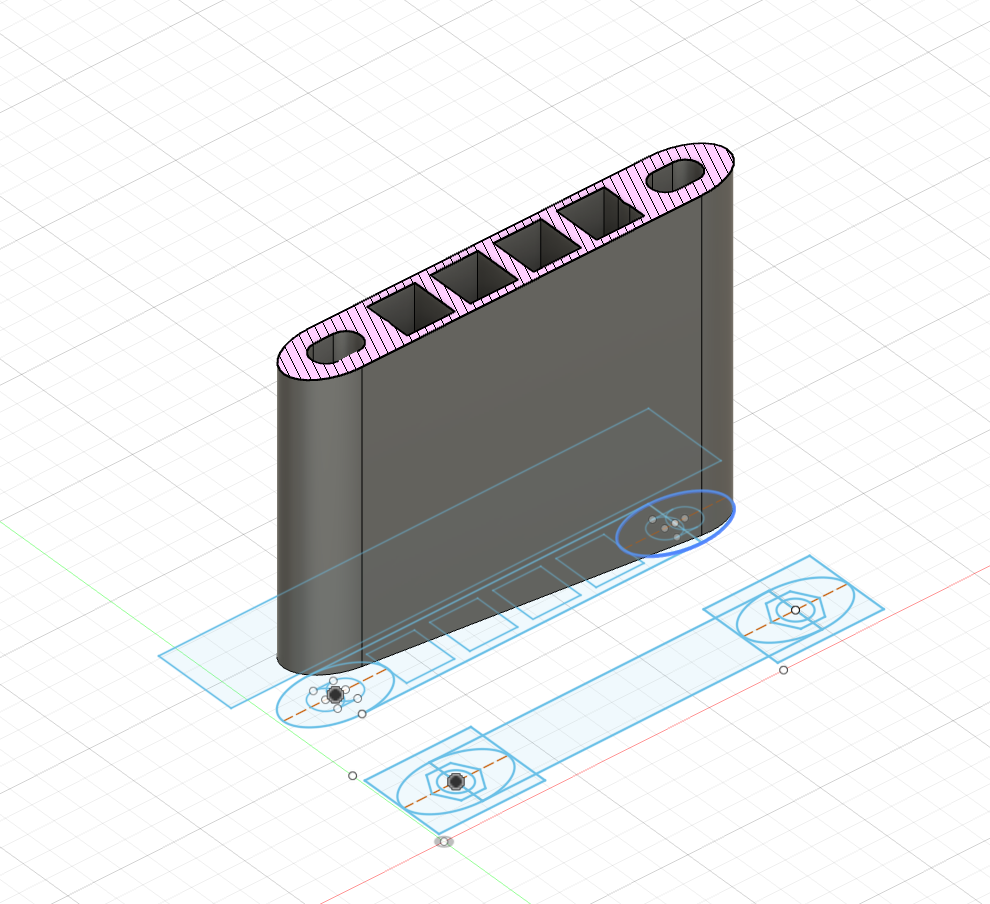

My first project was a simple chain ring cover (which would be the next version of the 3D printed aero cover I 3D printed here). The purpose of this cover is to streamline airflow over the crank while in motion to reduce the bikes Cda (Coefficient of Drag). aka. More slip streamed. read more

You must be logged in to post a comment.