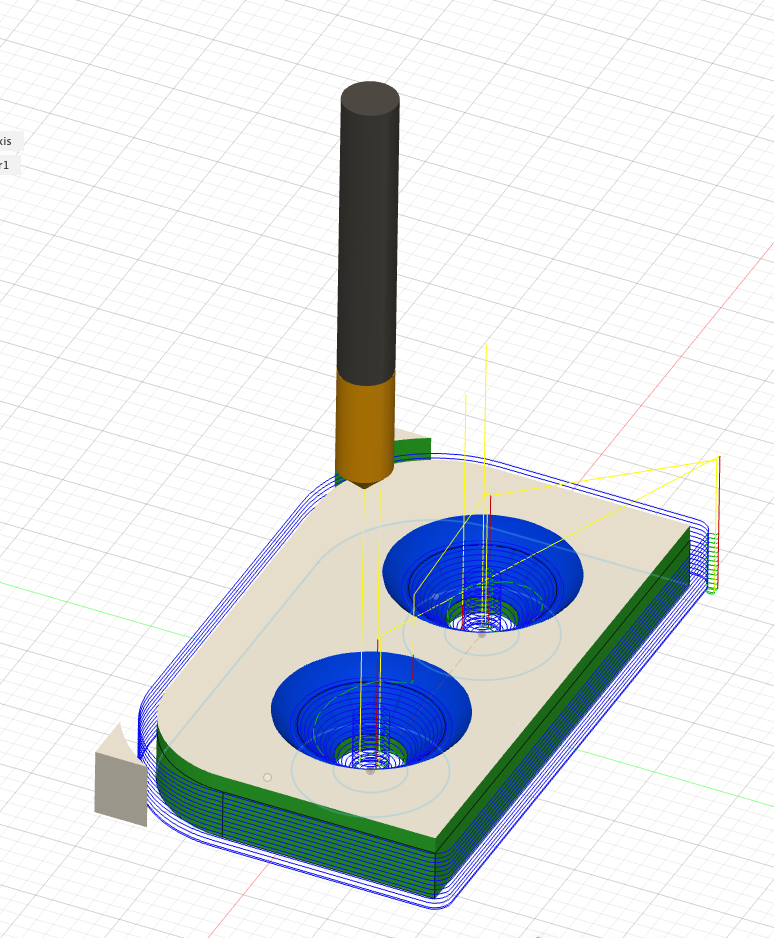

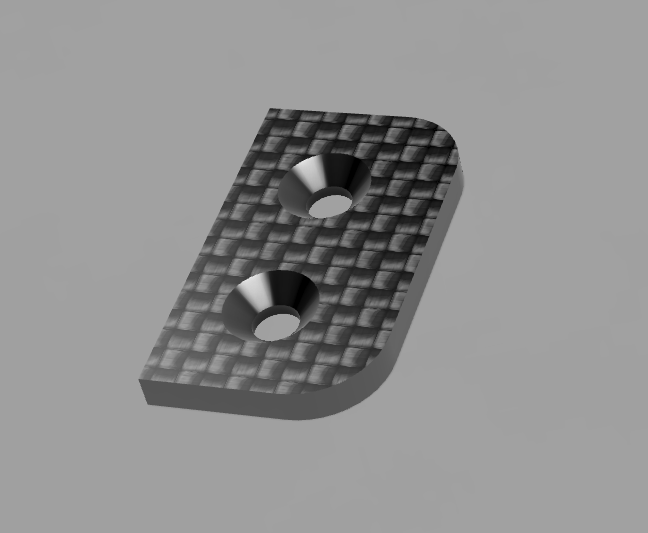

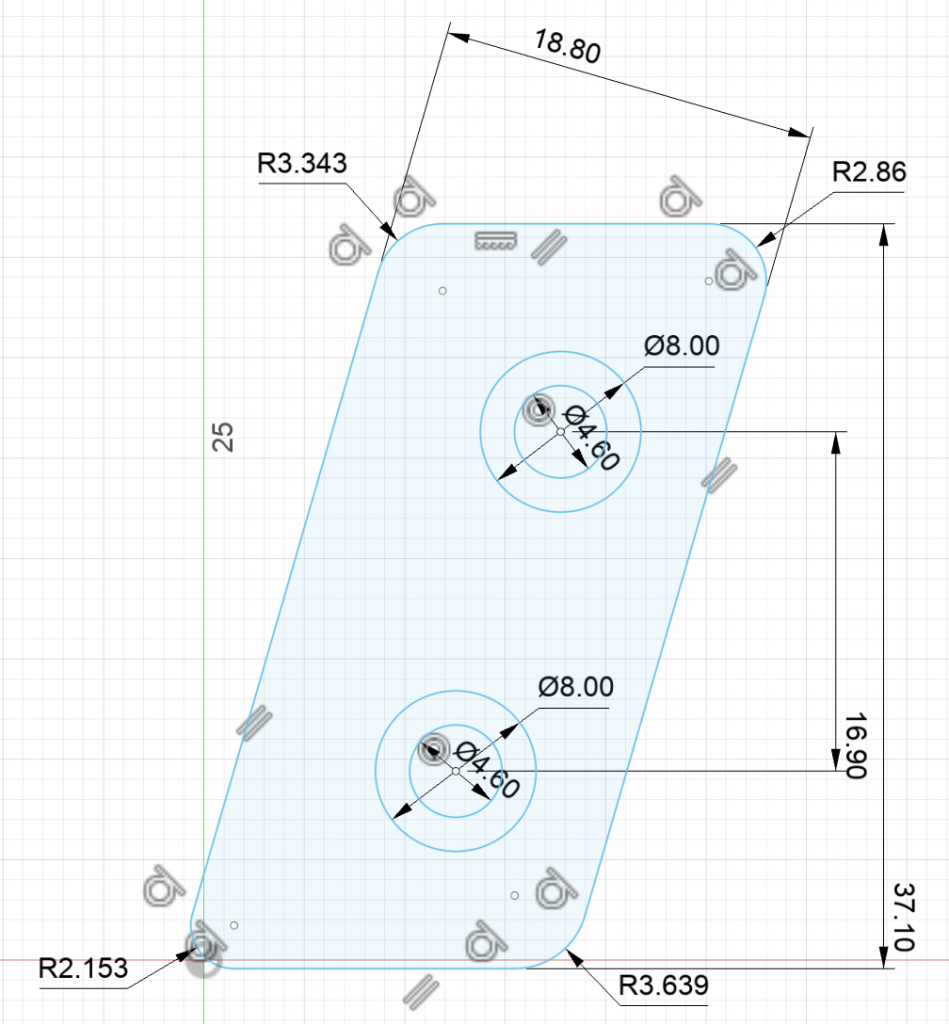

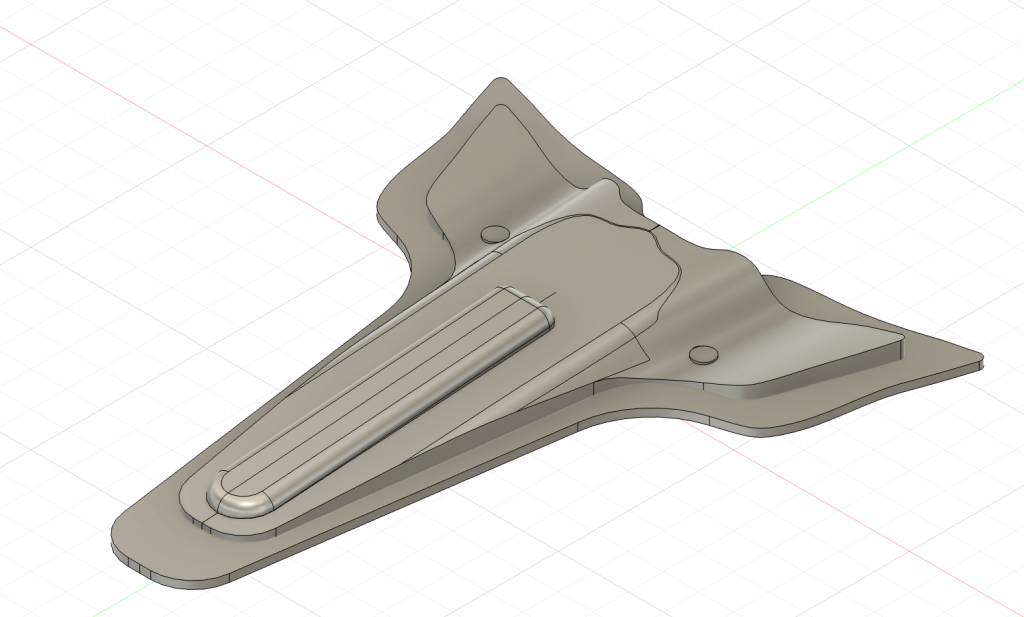

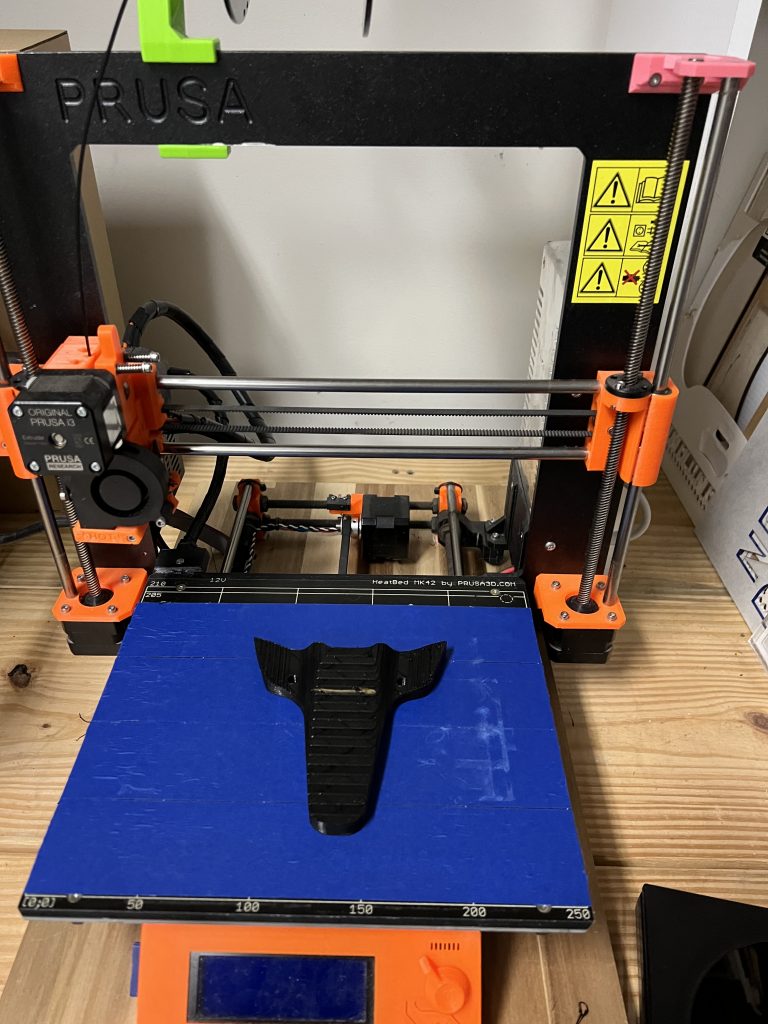

One benefit of owning multiple Canyon bikes is that the majority of them have had the same style/shape of stem caps. From my very first one until now, I have printed, CNC’ed, laser cut, and layed up over a dozen, each with some unique design or nuanced variation depending on the manufacturing method. This version was no different 🙂 I have been waiting to streamline the design to have it fit closer to the bar profile on my MTB. So this time I set out to CNC a mold, wet lay carbon into the mold, and then CNC the shape.

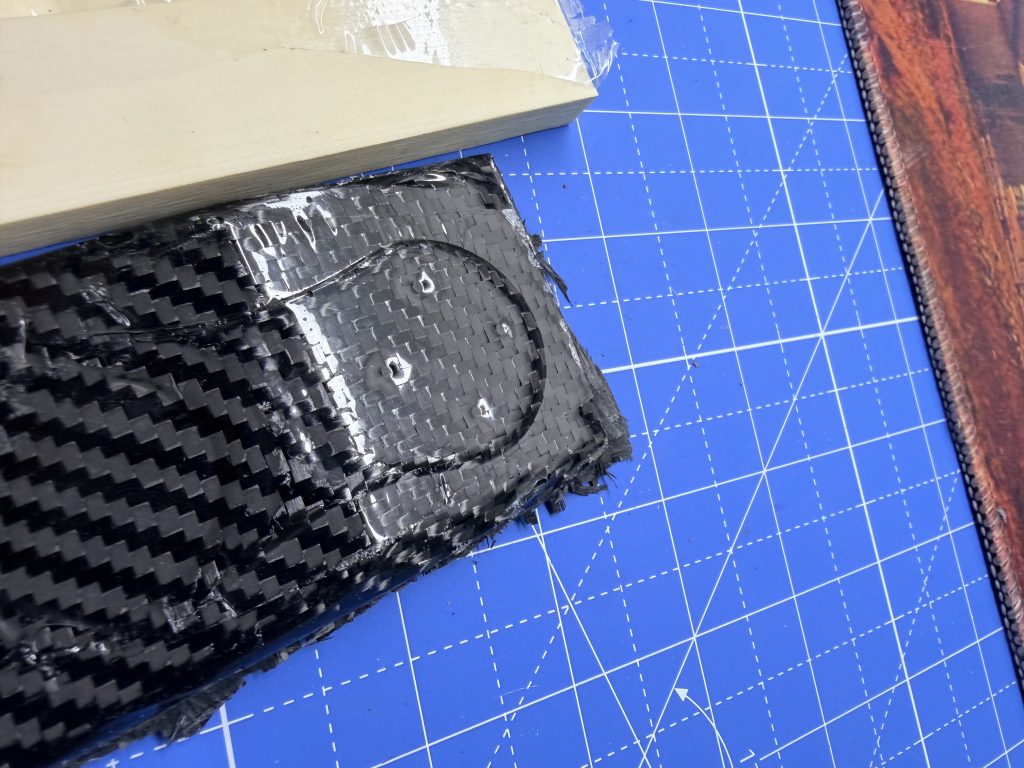

Variant 1: Failed 🙁 the shape worked quite well but the finish was ugly and would be a nightmare to CNC accurately.

Variant 2: Failed 🙁 I CNC’ed the shape using Aluminum, wet layed the carbon, but it cured into the mold and was unable to demold it successfully with delaminating/damaging the part.

You must be logged in to post a comment.