Young men speak about the future because they have no past, and old men speak of the past because they have no future.

Boyd K. Packer

DIY: Physical Random Number Generators & Double Slit Experiment

One of the benefits of Quantum Computing is their ability to generate truly random numbers.

Since classical computers are deterministic machines, governed by algorithms, they are inherently predictable. Therefor any number generated by a classical computer, even if it seems complex is actually based on a set of conditions or algorithm, which therefor makes it a “pseudo random number”, rather than truly random.

To generate truly random numbers you need to rely on a physical processor or phenomena that are unpredictable, examples of this include radioactive decay, electronic noise or even atmospheric noise.

Since QC is essentially based on a physical process and the probabilistic nature of quantum mechanics, its qubits can exist in a superposition state, this means they can represent a combination of 0 and 1 simultaneously, this state/property can be harnessed by QRNG (Quantum random number generators) to produce truly random numbers.

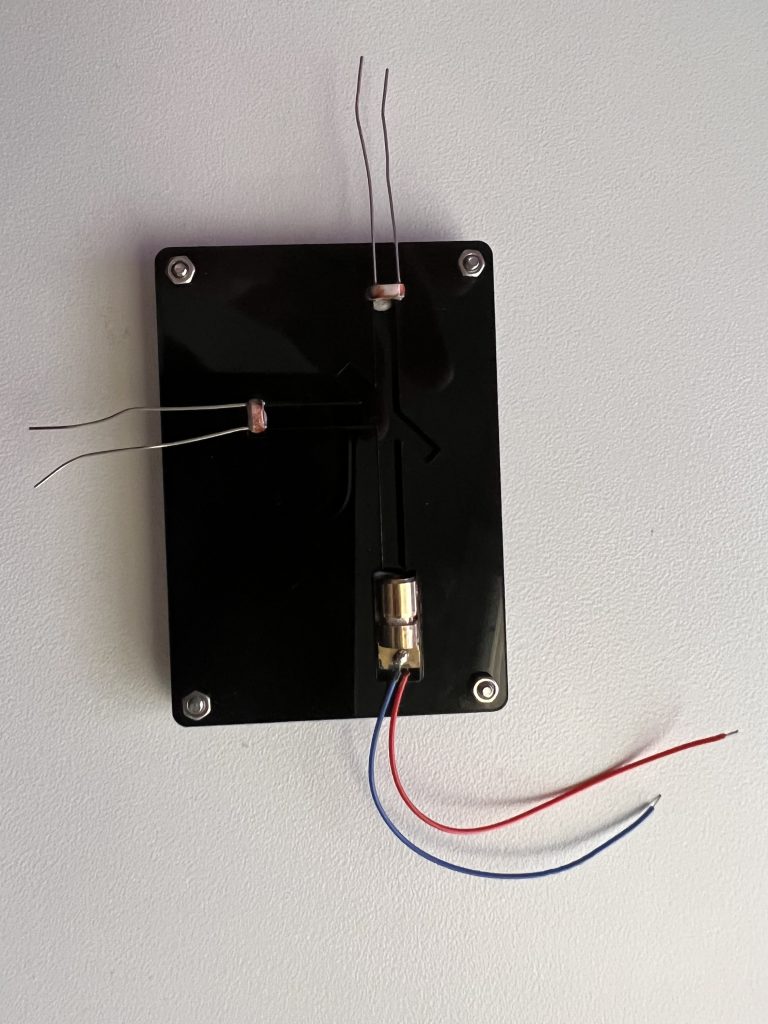

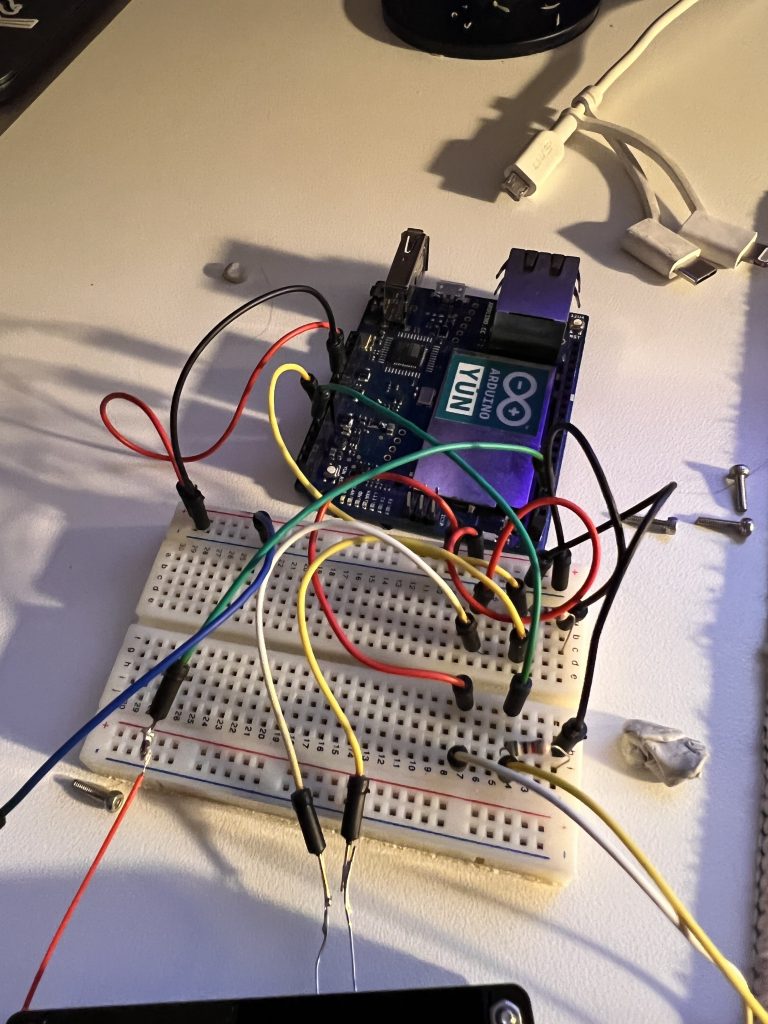

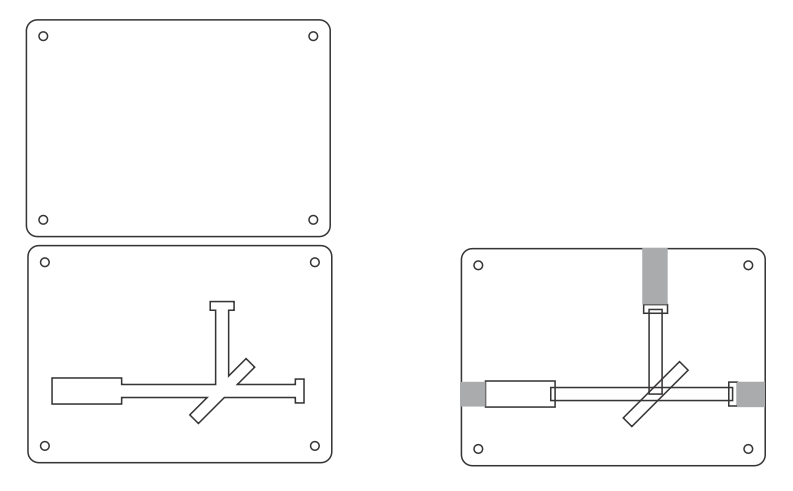

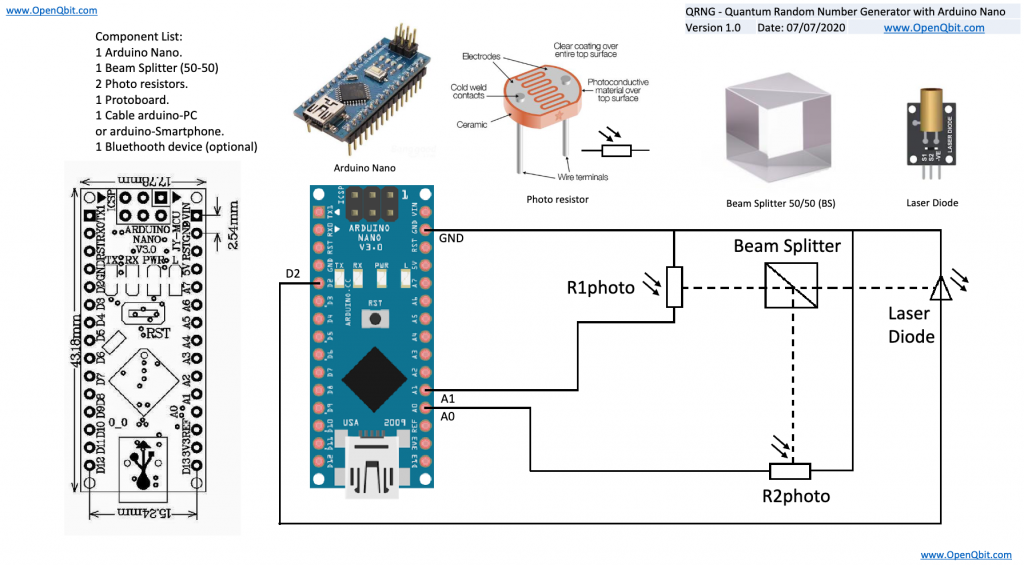

As a fun project, I decided to build a small physical QRNG using an Arduino, laser diode, beam splitter and two photo resistors. The basic premise is that you pulse the laser, it sends a wave/particle (both!) through the beam splitter, 50% of the time it should hit one of the two photo resistors, providing you with a random string of “1”s or “0”s.

While a very simple, basic and small example, it is a fun experiment. Check out OpenQbit.com if you would like to build your own. To make this a little easier, I laser cut a template/outline for the beam splitter for holding each of the components.

Enjoy Randomness? Check out these blog, sites, references: http://www.reallyreallyrandom.com

Non Quantum RNG generator using zener noise: http://www.reallyreallyrandom.com/zener/breadboard/

Nice video explaining the seed variables used and middle squares: https://www.khanacademy.org/computing/computer-science/cryptography/crypt/v/random-vs-pseudorandom-number-generators

/* Annotated QRNGv1 Firmware V1.1

Author: Noah G. Wood

Modified: Paul Aschmann

Copyright (c) 2019 Spooky Manufacturing, LLC

License: GPLv3.0

*/

int triggerPin = 2; // This pin will pulse our quantum circuit

int hPin = A0; // This pin measures the horizontal polarized photons

int vPin = A1; // This pin measures the vertically polarized photons

float H = 0;

float V = 0;

long previousMillis = 0;

long interval = 1000;

float maxH = 0;

float maxV = 0;

void setup() {

// Just setting up triggerPin and serial connection

//pinMode(13, OUTPUT);

pinMode(triggerPin, OUTPUT);

Serial.begin(9600);

}

int Random() {

// Pulse the laser

digitalWrite(triggerPin, HIGH);

//delay(1);

digitalWrite(triggerPin, LOW);

}

void loop() {

// The main program

// Run our program and print the random bit to serial

//delay(1000);

unsigned long currentMillis = millis();

if (currentMillis - previousMillis > interval) {

previousMillis = currentMillis;

Random();

}

// Read the photoresistors

H = analogRead(hPin);

V = analogRead(vPin);

// Determine random bit

if (H > V) { // More photons in the H mode, return 0

Serial.println("-------------------- > H: ");

Serial.println(H);

Serial.println("V: ");

Serial.println(V);

if (H > maxH) {

maxH = H;

Serial.println("New max H");

}

} else if (V > H) { // More photons in the V mode, return 1

Serial.println("-------------------- > V: ");

Serial.println(V);

Serial.println("H: ");

Serial.println(H);

if (V > maxV) {

maxV = V;

Serial.println("New max V");

}

} else {

Serial.println("Same values");

}

delay(1000);

}

Generating Random Numbers with QisKit & IBM Quantum Hardware

Generating true random strings using classical computers is not as easy as you may think. Unlike deterministic processes that follow specific algorithms and patterns, achieving true randomness poses a challenge in the realm of classical computing. Classical computers operate based on predetermined instructions and logical operations, which inherently lack the inherent unpredictability required for true randomness.

In contrast, true randomness involves an element of unpredictability that goes beyond the deterministic nature of classical computing. Attempts to generate random strings on classical computers often involve algorithms that simulate randomness, but these are ultimately constrained by the deterministic nature of the underlying hardware and software.

List: My Apps

List of Mobile Apps I have designed, developed and published, mainly under the Lithium Labs umbrella.

Generative Art Resources

During the NFT hype, generative art got a lot of attention due to its ability to programmatically, and algorithmically generate designs and art. These are a few resources I used and developed digging a little bit deeper into the subject.

Skill Share Course: https://www.skillshare.com/classes/Programming-Graphics-I-Introduction-to-Generative-Art/782118657

Glowforge Notes

We have owned a Glowforge since their introduction and it has been a fun tool to work with. Here a few of my notes on cutting various materials, some acronyms and details which I found useful on this learning journey.

Terminology

- On really hard material, just assume the kerf is 0.002″ (0.05mm).

- In general, kerf on PG hardwood is about 0.002″, and 0.002-0.022″ in general.

- PG Medium Maple has a kerf around 0.008″.

- PG Draftboard has a kerf around 0.002″ (use 0.05mm – 0.06mm; 0.05 is barely loose; 0.055mm is good).

- PG Acrylic has a kerf around 0.002″ (0.05mm).

- Zebrawood, Purpleheart, and other really hard woods have a kerf around 0.002″ (0.05mm).

- For inlays: Take half the kerf from the outside material (small hole) and half the kerf from the inside material (fill hole). Increase the inside/fill material’s size by this amount. If the outside material is flexible (e.g., wood) and you want a really tight fit, increase the size of the inside/fill material by another 0.001″. For inflexible (acrylic, hardwoods), you might add 0.0005″ for a really snug fit.

- Inlay: Acrylic in Medium Maple: Increase acrylic by 0.020. Using 0.015 can be finger-pressed in but also pops out easily. Using 0.017 can still be popped out. However, if 0.020 doesn’t fit in the first time, then first put in 0.017 and then pop it out. That will stretch the hole just a little so the 0.020 fits tightly and will never come out.

- Inlay: Acrylic in Medium Draftboard: (TBD) Increase acrylic by 0.025. The kerf from draftboard is larger than a hardwood like medium maple.

Cost to Deploy a Contract on the Ethereum Network

The cost of your deployment is based on 5 things, with a 6th affecting the estimated cost of deployment:

The flat fee of 32k gas. The CREATE op code, which is called during contract creation, costs a fixed 32k gas. This is of course on top of the 21k gas of a normal tx. Note: During contract creation from an EOA (non-contract address), the CREATE opcode isn’t explicitly called. The return value of the tx is actually used to create the contract, but the fixed 32k fee is the same. The amount of bytecode in the compiled contract. More bytecode means more storage, and each byte costs 200 gas. This adds up very quickly. Note that inherited parent contracts are also included in the bytecode. The TX data. All the bytecode your sending as tx data costs 68 for non-zero bytes and 4 for zero bytes. The code actually runs before creation of the contract, e.g. the constructor of the contract. If the constructor requires a lot of computation to generate the bytecode, then it’ll be even more expensive. The gas price. The higher gas price you use, the higher it will cost. Seeethgasstation.info

Bookmark: Traveling around the US?

Here are a few random things to do …

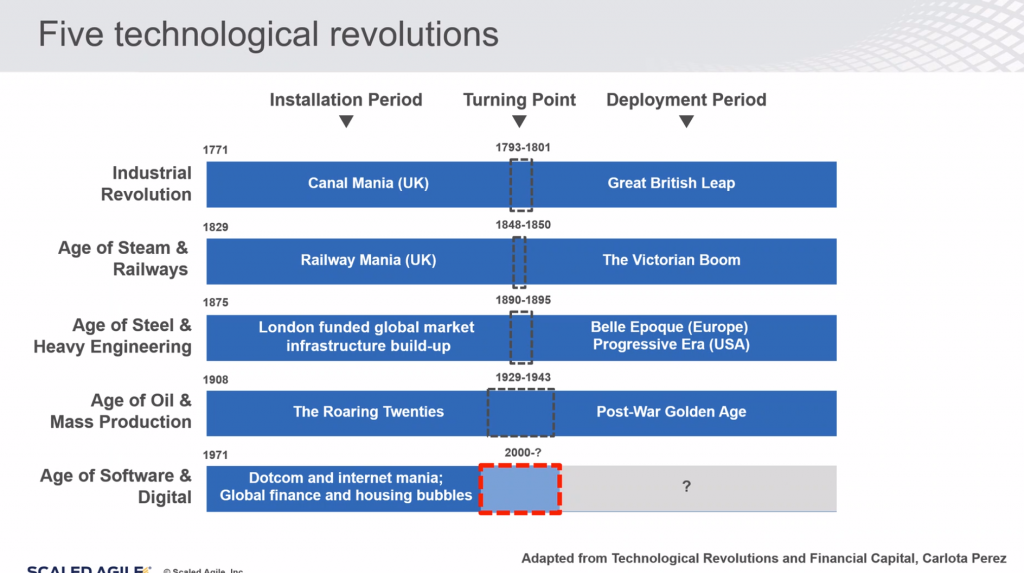

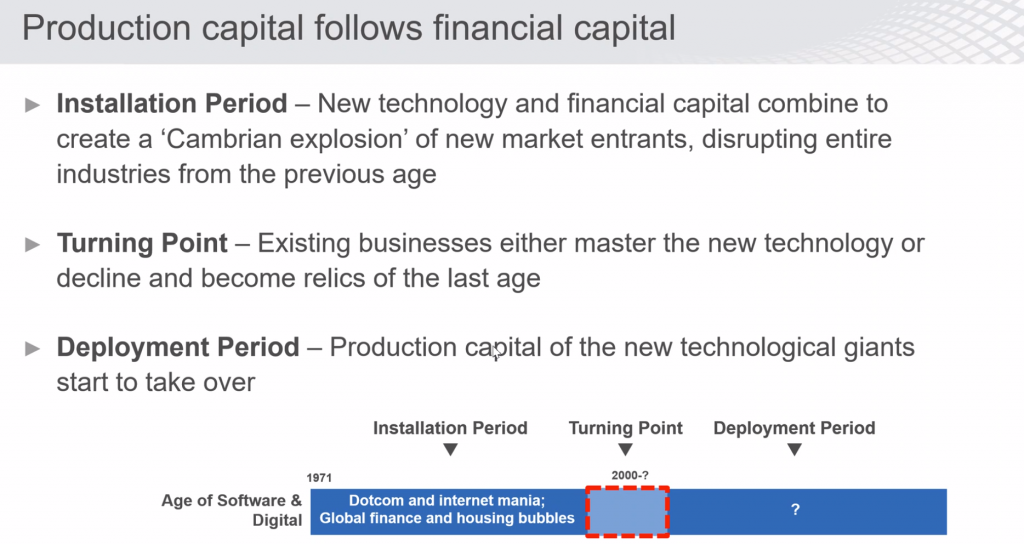

5 Technological Revolutions

I am currently doing a SAFe Training (Leading SAFe) and this was one of the slides shown, it really resonated with me and wanted to save it for posterity … I am wondering where we are in the progression of the Software & Digital Age …

Quantum Hardware – Notes

Dilution Refrigerator, uses liquid helium

Absolute zero, optimal operating temp – 273 celcius

Top to bottom – different stages of cooling, filters, amplifiers

Sample holder holds quantum processor

CPU vs QPU

CPU – data/voltage/1’s 0’s flows through the gates (and, or, xor, etc.)

QPU – Data is on the chip, circuit is on the chip, pulses are sent to the chip

chip created by lithography, metal deposition, all, oxide, etc.

Quantum Gates

Called block sphere

Pulses represent the gates.

Rotate qubit from ground state to 1

Example: Ex Pi rotation

Send another pulse, Pi/2

Quantum Entaglement

2 Qubits, and some interaction between them

When you entangle boxes, you can change probablities

You must be logged in to post a comment.