My next foray into Carbon fiber design, tooling and development came with this project. Overall, a reasonable success. Still not perfect, and probably will not be used due to the catastrophic risk associated with riding a bike at 50mph and these breaking, but in theory and practice, a great learning opportunity.

Inspiration

Part 1: Prototyping

Part 2: Design

Fusion 360 for the design work.

Part 3: Tooling/Plug

This consisted of 4 3D printed cubes glued together and then finished with lots of sanding, and an epoxy coat.

Part 4: Version 1

The first version didnt go according to plan, I ran out of Carbon fiber material, and also recognized some layup issues. I decided to finish it anyway, but it was a dud 🙁

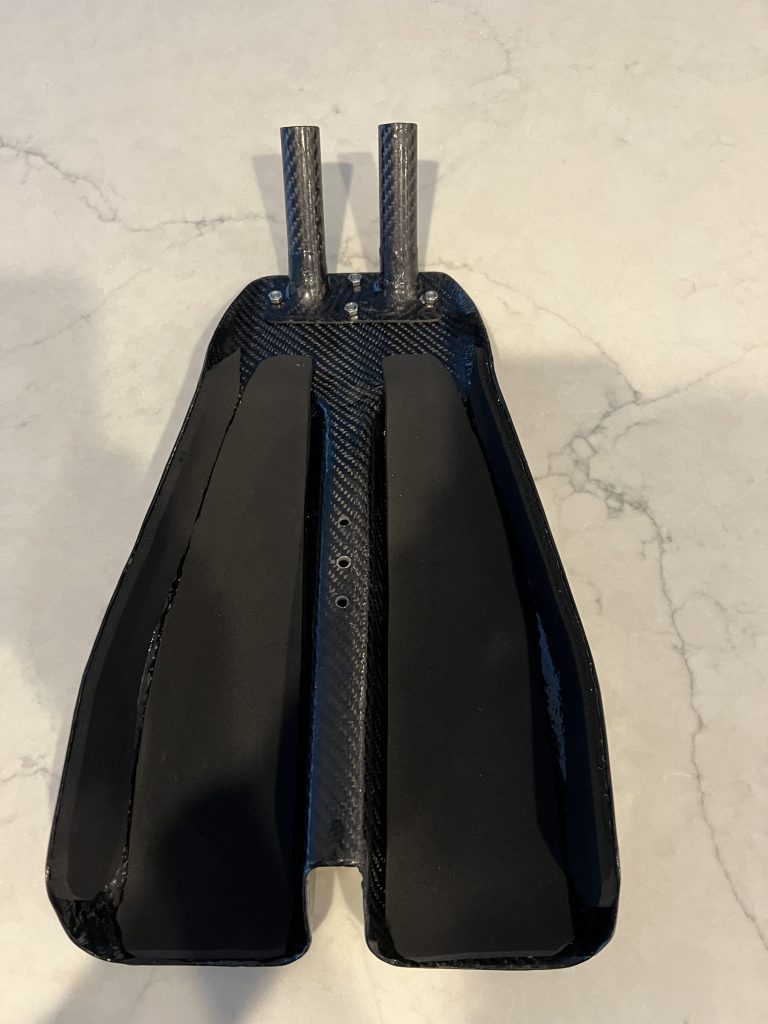

Part 5: Version 2 (Final)

Build up and the first real pull from the mold was somewhat successful. The peel ply wasn’t laid down great which left some wrinkles, but since I was going to epoxy both sides, I wasn’t concerned.

Sanded and clear coated, added some foam padding and made some handles, I think overall as a prototype it turned out OK 🙂

You must be logged in to post a comment.